Ventus Shut-off Valve System

IN CONFORMITY WITH DIN EN ISO 7396-1

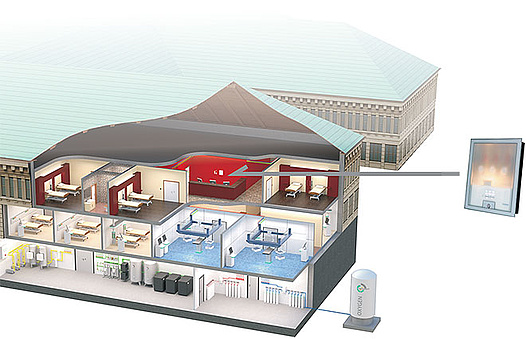

According to DIN EN ISO 7396-1, zone shut-off valves must be available in front of each functional area (operating room, intensive care nursing, normal wards, ...).

The zone shut-off valves must be located in boxes with solid covers or doors. In addition to the shut-off valves, such a box must also contain a physical separation line and an emergency intake point. The door must be locked in its closed state, but must be accessible quickly in an emergency (emergency opening). The Ventus shut-off valve system fullfills all of these requirements.

Furthermore, emergency operational alarms are integrated in the Ventus system. Pressure sensors continuously monitor the network pressure. The electronics permanently monitor the measured value and compare it with the alarm limits. If the value exceeds or falls below the pressure limits there is a visual and acoustic signal (clinical emergency alarm). There are various options for the electronics such as digital display, flow measurement, network integration or logbook storage of all alarms and actions.